Product Information

Attachments

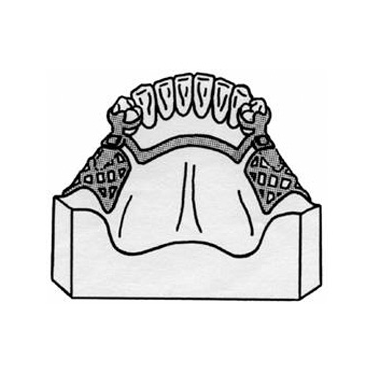

The Distal Stress Eliminator (DSE) Hinge is a bilateral clasp retained free end removable partial dentures designed to reduce loading or torqueing of abutments. The unique design provides for easy freeing after casting and provides total lateral stability.

Indications

For use on mandibular bilateral clasp retained free end removable partial dentures to reduce loading or torquing of retaining abutments. Allows patient comfort and abutment protection by allowing independent unilateral function eliminating torquing leverage on the abutments on the nonfunctioning side.

Features

- Small size allows utilization in short vertical spaces and provides for good esthetics. Universal size: width of 3.0mm and a vertical height of 1.5mm.

- May be used on both conventional clasp cases and in conjunction with a variety of precision attachments

- Unique design provides for easy freeing after casting and provides total lateral stability

Instructions for Use

- Create a refractory model to wax up the removable partial denture framework.

- Design clasp of framework as prescribed by the dentist.

- Lute the knuckle of the DSE Hinge to the clasp, as close to tissue as possible. Position the DSE Hinge with Trunion pointed up. When attaching the DSE Hinge to the wax-up of the framework, the Trunnion must be in contact with the distal cross bar of the Knuckle.

- Finish waxing the distal saddles. Lute the saddle to the Trunnion of the DSE Hinge with wax, covering the top of the Trunnion.

- The Trunnion is design to be Cast-to and the saddle will remain in position with mechanical retention.

- Sprue the mesh saddle to the rest of the partial denture framework.

- The Trunnion contained within the hinge Knuckle must remain free of wax.

- Invest for casting.

- The completed casting is removed from the investment and cleaned. Leave the button attached to provide a firm hold. Cut off the sprue connecting the mesh saddle with the clasp unit.

- Active the hinging movement of the DSE Hinge. It should freely hinge with finger pressure. The oxidation of the Trunnion during burnout acts a separator with the Knuckle.

- Complete acrylic wax up and processing as normal.

- To activate the hinge movement to the final prosthesis, heat is applied to the exposed metal near the hinge unit. The heat transfer will soften the acrylic around the hinge. Use an electric soldering iron or hot spatula to deliver the heat. Move the partial denture saddle up and down and maintain this movement until the metal cools.