Hello

Preat is setting the standard with advanced Patient-Specific Abutment solutions. With our innovative angled screw channel abutment, offering up to 30° of angulation, we’re not just supporting your workflow — we’re empowering your ability to provide the best restorations possible!

From fully validated in-house milling to expert overflow and outsourcing support, you have the freedom to own your own strategy, meeting your needs today and accelerating your growth tomorrow.

PATIENT-FRIENDLY PACKAGING

Every Patient-Specific Abutment ships with two screws: one for use during fabrication and another kept pristine for final clinical placement. It’s our way of helping you deliver the best possible outcome for the patient.

Preat Patient-Specific Abutment Features

CUSTOMIZATION

Variable 0-30° Angled Screw Channel

Customize beyond emergence profile and margin design with angled screw channels up to 30°. This flexibility, combined with our implant compatibility, gives you unmatched restorative confidence to meet the needs of each case.

COMPATIBILITY

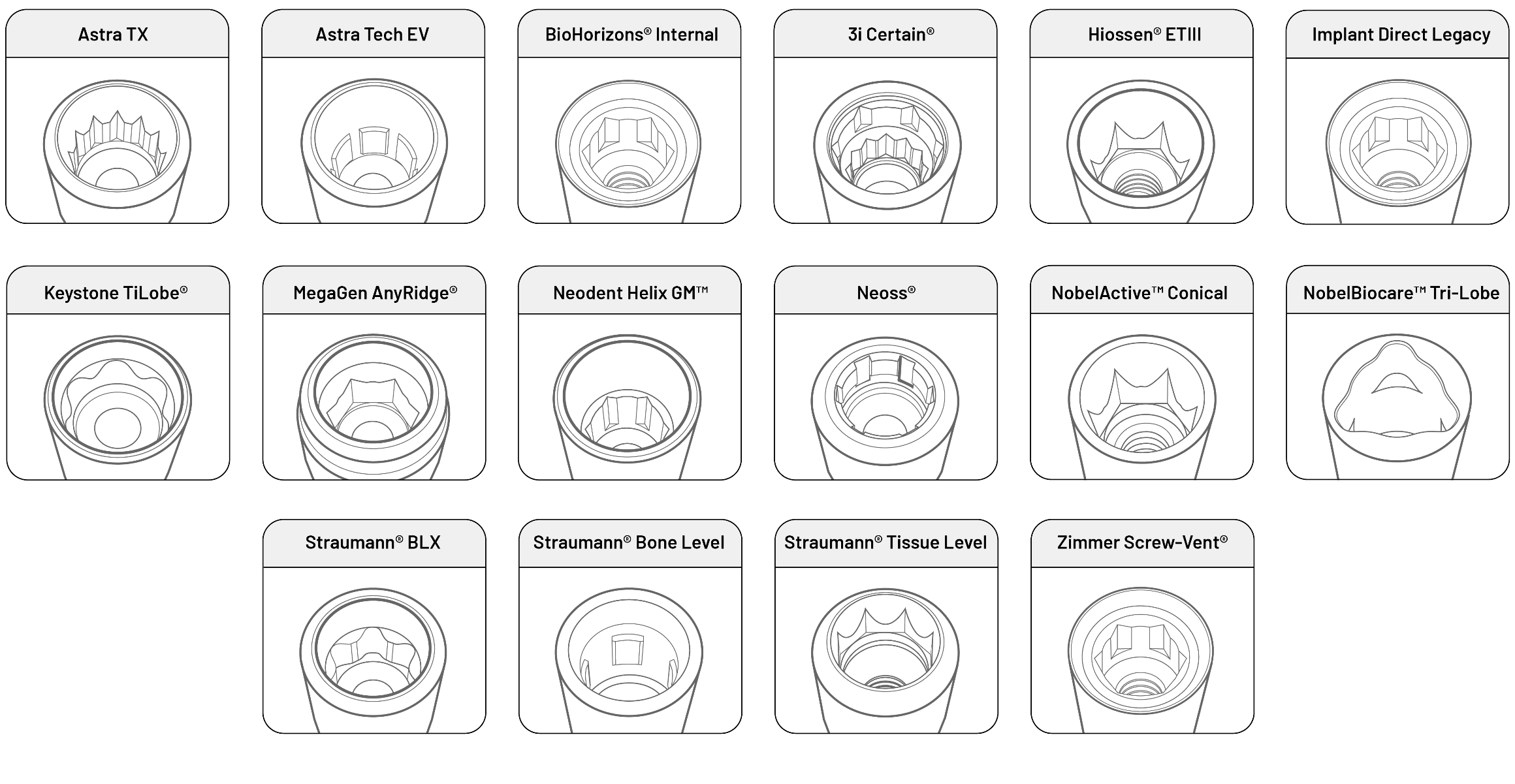

Compatible With All Major Implant Systems

Standardize your workflow with one trusted partner for the majority of your custom abutment cases. Preat patient-specific abutments — including new angled screw channel options — are compatible with longtime market leaders like NobelActive™, newer designs such as Straumann® BLX, and even niche sizes like BioHorizons® 3.0.

SPEED

2 Day In-Lab Turnaround Time

Deliver great smiles quickly for the ultimate wow factor. Need we say more?.

QUALITY & PROTECTION

OEM-Level Precision, Backed by Warranty Confidence

Preat patient-specific abutments are manufactured from our 510(k)-cleared titanium blanks and independently tested to meet or exceed the fit of OEM abutments. You get the precision you expect and the protection your patients deserve. Plus, we match all OEM implant warranties, giving you full confidence in the integrity, durability and long-term performance of every case.

Abutment Design Your Way

DESIGN IN-HOUSE

The Preat Choice Library streamlines your workflow and improved productivity with advanced scan acceptance and a single library compatible with 40+ implant interfaces.

Now featuring intuitive Angled Screw Channel design tools, our library supports precise angulation adjustments up to 30°, along with clear visualization for screw access trajectory and titanium blank indexing.

Built for efficiency and flexibility, the library integrates seamlessly with both 3Shape® and exocad®, delivering the freedom to customize restorations while working within FDA-cleared parameters.

DESIGN WITH OUR EXPERTS

We’re happy to design for you. Just upload the intraoral or model scan when submitting your case, share your input on key design aspects and our experts will take it from there. Our designers have, on average, 20+ years at the bench and aim to create the best restoration possible for each patient. Order Now >

MORE THAN AN OUTSOURCE PARTNER

If you’re ready to bring abutment milling in-house, Preat makes it easier than ever. With our FDA-cleared PNP process, your lab can start milling pre-milled blanks without becoming a validated milling center. Stay compliant, stay in control and grow your capabilities confidently. Learn More >

Compatible with All Major Implant Systems